Conquering the Backyard: Why You Need a 24 Volt Tractor (and How to Find the Real Pros)

If you’re searching specifically for a 24 volt tractor, chances are you’ve already figured out that the standard 12V models simply aren't cutting it. Whether you're a parent battling a slightly sloped yard, a retailer looking to reduce warranty claims, or an enterprise buyer needing reliable stock, the move from 12 volts to 24 volts is a fundamental change—it’s not just an upgrade, it’s a different ballgame.

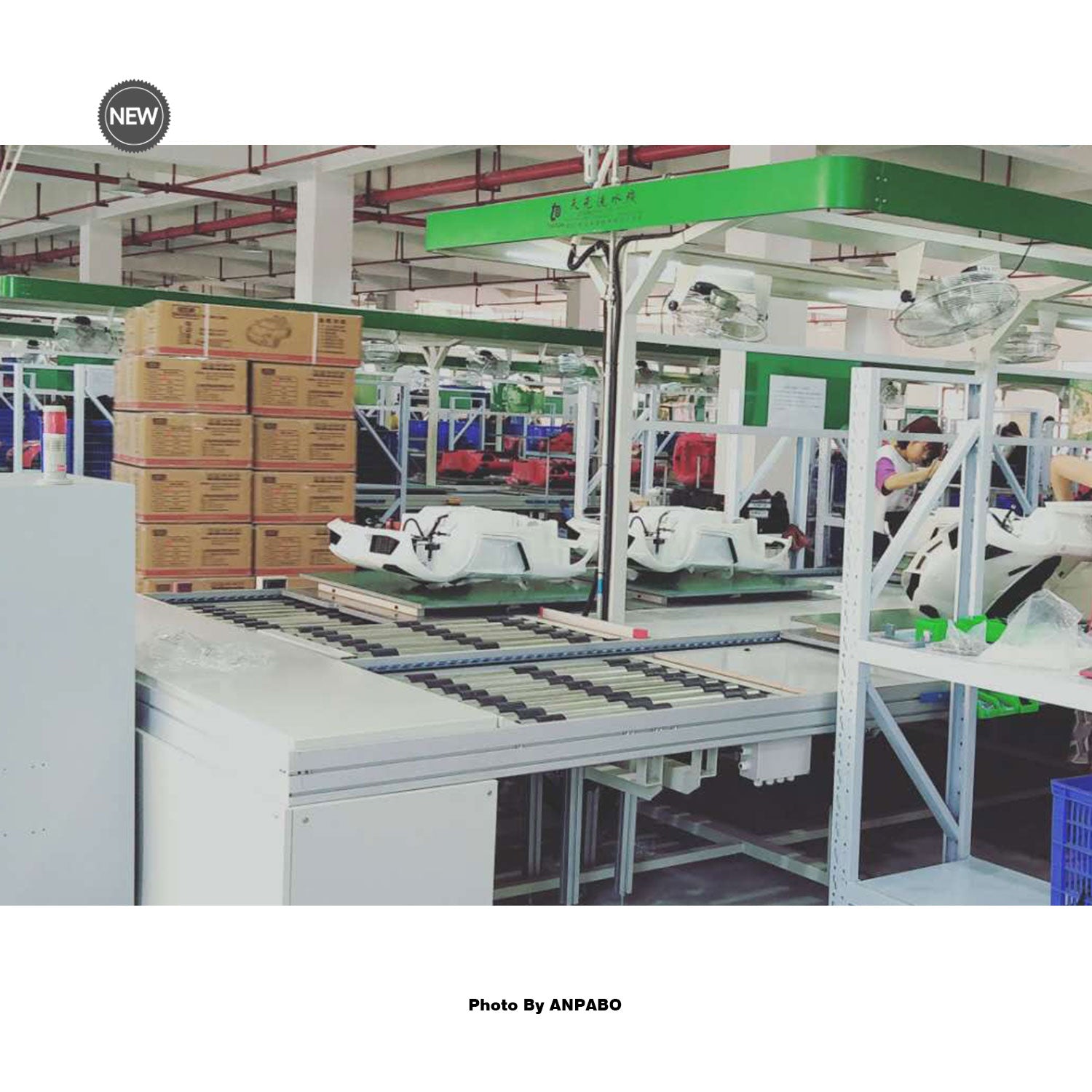

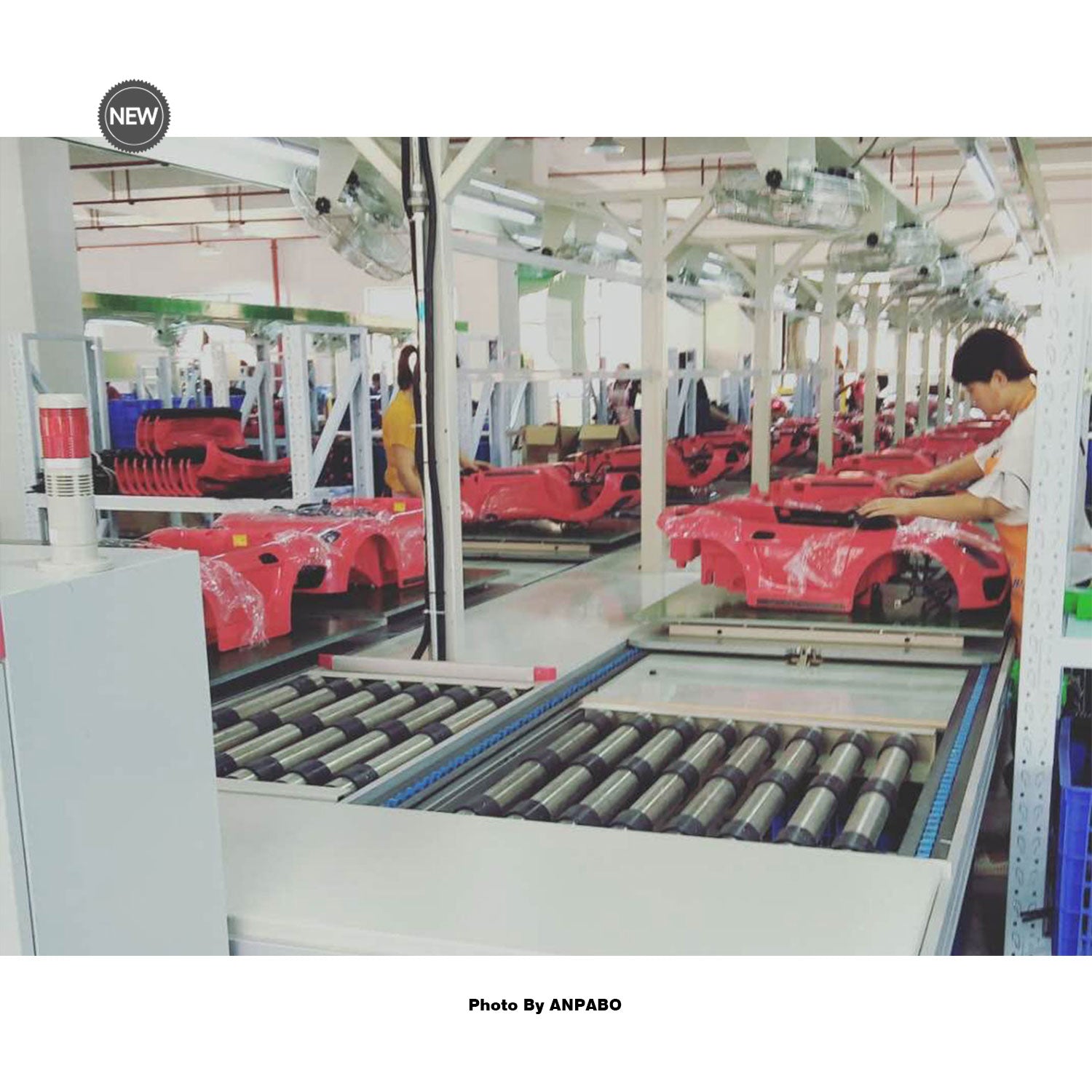

We, as R&D specialists and a direct manufacturing source for high-performance children's ride-on cars, approach the 24V segment purely from an engineering standpoint. The voltage boost isn't just about speed; it’s about sustained torque and the ability to handle higher current draw without prematurely stressing the motors. A 12V system might peak at a decent speed, but put it on grass or gravel with two kids onboard, and watch the voltage sag and the thermal breakers trip. A well-engineered 24V system maintains power delivery under load, providing the reliable, non-stalling performance that today's North American customers expect.

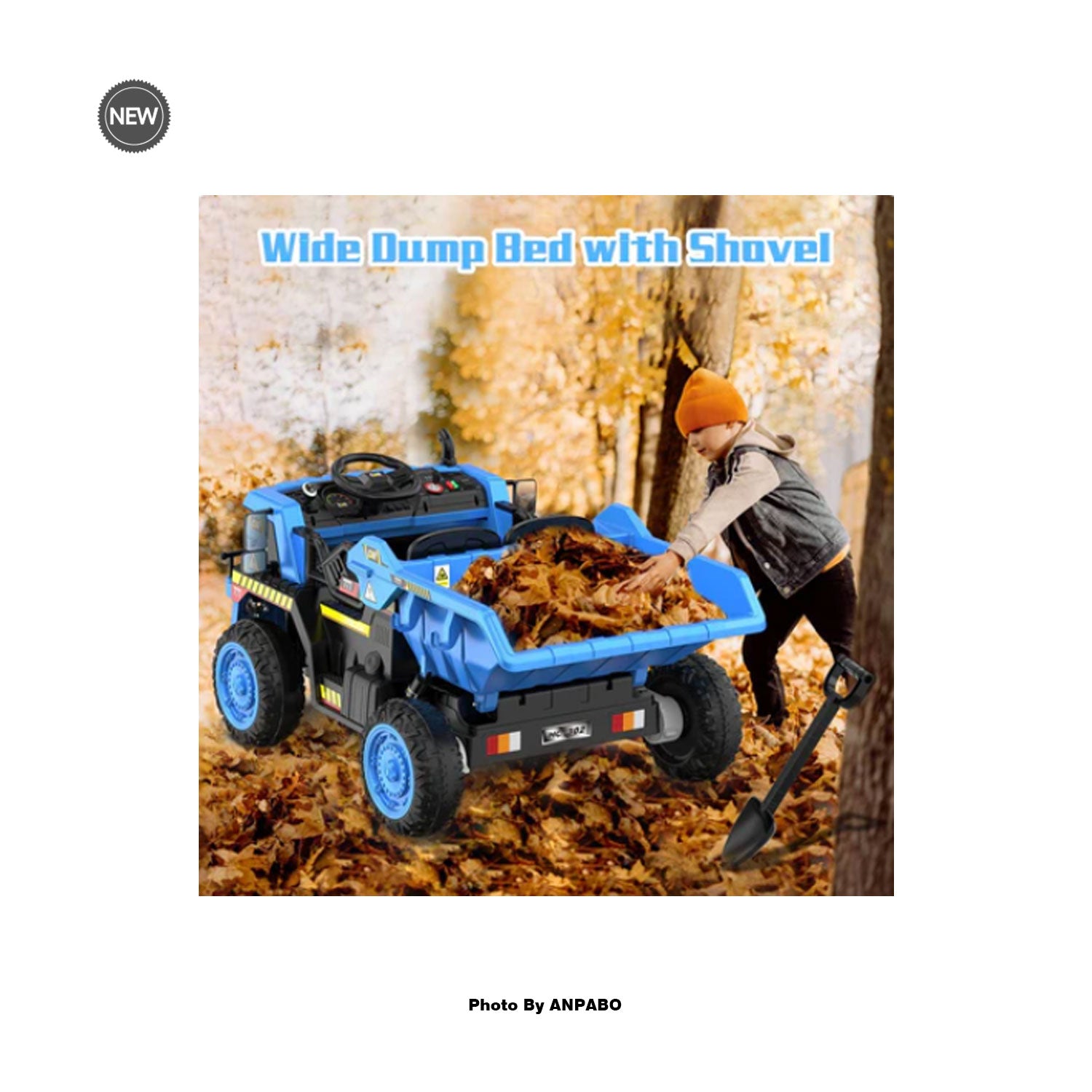

For manufacturing and supply partners, understanding this distinction is critical for your bottom line. Take Eleanor, the inventory manager for a major Midwest regional toy chain. She noted a 35% higher return rate on entry-level 12V two-seater utility vehicles compared to their newer 24V counterparts, even though the 24V models had a 20% higher price point. Why? The performance matched the expectation. When a customer buys a mini-tractor or a ride on dump truck, they expect it to actually haul a small load and handle the backyard terrain. The 24V architecture delivers on that promise, leading to happier customers and significantly fewer operational headaches for the retailer.

The Engineering Advantage: What Makes 24 Volt Superior

The power upgrade requires a total system overhaul—it's not just swapping out the battery. When we design a high-power ride-on, particularly a heavy-duty model like a 24 volt tractor, we don't just double the battery pack. We design the entire drivetrain around the new specification.

Robust Design Factors for 24V Systems

-

Motor Selection: We use higher-spec motors designed for 24V operation, which inherently handle load better and run cooler, extending the product’s lifespan.

-

Wiring Harness: Thicker gauge wiring prevents excessive heat buildup and ensures minimal voltage drop, maintaining power delivery.

-

Gearbox Integrity: The gearboxes are reinforced to handle the increased rotational torque delivered by the 24V motors, reducing the risk of gear stripping—a common failure point in poorly upscaled 12V models.

This attention to durability is paramount for our B2B partners, whether they are an enterprise purchasing a fleet or an e-commerce platform like the one managed by David from Toronto, who specializes in premium outdoor toys. David looks for suppliers who can guarantee low Defective Rate on Arrival (DOA), and the engineering robustness of 24V systems is the only way to consistently achieve that in this product category.

Case Study: Solving the Hillside Challenge with 24V Power

Consider the common scenario faced by Sarah, a busy CEO with two energetic toddlers in suburban Massachusetts. She bought a popular 12V Jeep-style ride on car for her kids to use on their gently sloping property. Within two weeks, the Jeep was frequently getting stuck on the small incline and often required a 'parent push.' Sarah's initial reaction was frustration, believing the toy was just faulty.

When Sarah contacted our technical support team, the issue wasn't a faulty battery, but a mismatch between the 12V power system and the actual application (slopes, heavy use, multi-child load). Our expert advised her that for her specific needs, she required the sustained power and high-torque capability of a premium 24 volt tractor or UTV model.

We guided her to a specific dual-motor 24V unit (e.g., the ANPABO 'Mega-Hauler' 24V UTV, which featured high-traction rubber strips and a reinforced chassis). The result? The kids conquered the slopes, the fun factor increased exponentially, and Sarah's frustration vanished. More importantly, she realized that purchasing high-quality, properly engineered toys saves money and aggravation in the long run. Our role shifted from simple supplier to technical problem-solver for her family's playtime needs.

When you're dealing with advanced electric ride on toys, you need more than just a box shifter. You need an R&D partner who understands battery chemistry, motor physics, and gear ratios. Whether you are Jane from a procurement department, or an individual buyer looking for a reliable One Seat Ride On Cars or the ultimate 24 volt tractor, access to direct factory expertise is the key to solving issues, reducing returns, and ensuring lasting customer satisfaction.

Getting the Right Support for Your Ride-On Fleet

Look, whether you're dealing with a simple battery drain issue on a ride on car, a gearbox fault on a ride on dump truck, or you need to source the next generation of high-performance electric ride on toys, you need clear answers and reliable products. Ditch the guesswork and talk directly to the people who design and build these vehicles. If you're ready to purchase a proven, high-quality 24V unit, or if you simply need expert troubleshooting and after-sales support for your current fleet, our R&D specialists and manufacturing team are here to help. Contact us to cut through the confusion, secure reliable inventory, and find the perfect, high-torque solution for your needs. We're the pros who can actually fix the problems and get the kids back to playing.